What is intelligent storage system for SMT?

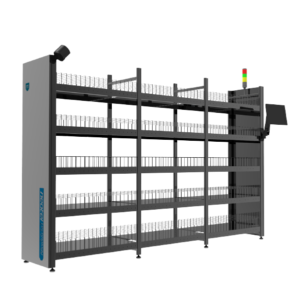

An intelligent storage system for surface mount technology (SMT) is a type of automated storage and retrieval system that is specifically designed to support the production of surface mount technology (SMT) electronic assemblies. These systems are used to store and organize the various components that are used in the production of SMT assemblies, such as printed circuit boards (PCBs), surface mount devices (SMDs), and other small parts.

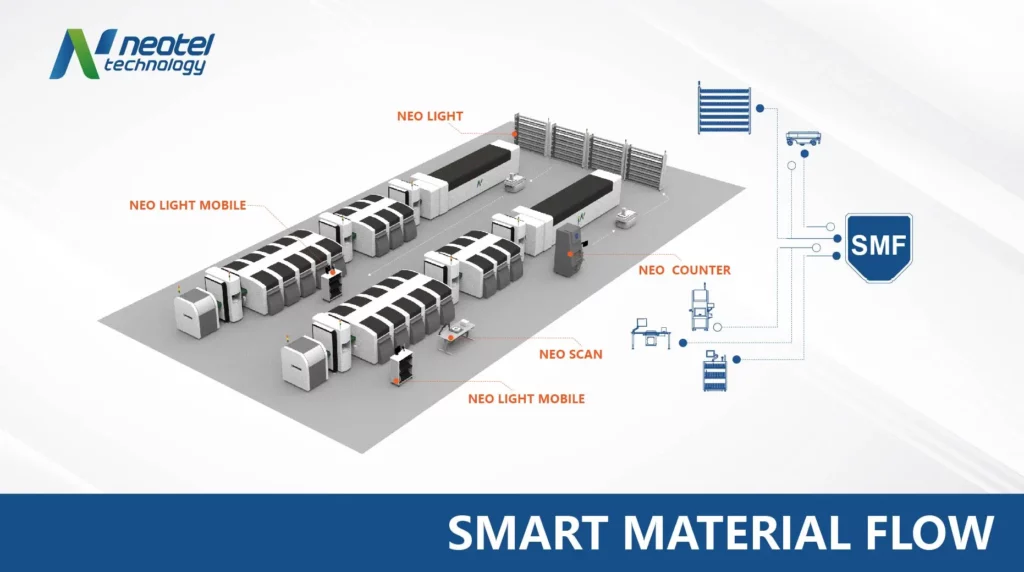

Intelligent storage systems for SMT typically feature advanced automation and control technologies, such as machine vision and robotics, to enable fast and accurate handling of components. They may also include features such as real-time inventory tracking, barcode scanning, and integration with other production equipment and software systems.

Intelligent SMT storage project implementation

An intelligent storage system is a type of storage system that is designed to optimize the use of available storage space and improve the efficiency of inventory management. There are a few key steps that you can follow to implement a smart storage project:

- Identify the goals of the project:

- Before you start, it’s important to clearly define the goals of the project.

- What do you hope to achieve with the smart storage system?

- Do you want to improve inventory management, reduce storage costs, or increase the efficiency of your warehouse operations?

- Before you start, it’s important to clearly define the goals of the project.

- Conduct a storage audit:

- The next step is to conduct a storage audit to assess your current storage system and identify areas for improvement. This may involve analyzing the layout of your warehouse, the types of products you are storing, and the volume of traffic in the warehouse.

- Design the smart storage system: Once you have identified the goals of the project and conducted a storage audit, you can start designing the intelligent storage system. This may involve redesigning the layout of the warehouse, implementing new storage technologies (such as automated storage and retrieval systems, even AGV), or introducing new inventory management software.There are several factors to consider when designing an storage system:

- Storage density: How many components can be stored in a given area?

- Throughput: How many items can be stored and retrieved per hour?

- Flexibility: Can the system handle a variety of different products and storage configurations?

- Accuracy: How accurately can the system locate and retrieve items?

-

- System integration

- These systems use software to monitor and manage the allocation and utilization of storage resources, as well as to provide features such as data protection, data tiering, and storage virtualization. Some common software aspects of intelligent storage systems include:

- Monitoring and management tools: These are used to monitor the performance and utilization of storage resources, and to manage the allocation of storage capacity to different applications and users.

- Data protection and recovery tools: These are used to protect data from loss or corruption, and to recover data in the event of a failure or disaster. This can include features such as replication, snapshotting, and backup and restore.

- Data tiering and storage virtualization: These are used to optimize the use of storage resources by automatically moving data between different types of storage media, or by virtualizing the storage environment to make it more flexible and scalable.

- Data analytics and reporting: These are used to analyze and report on the usage and performance of storage resources, and to provide insights into trends and patterns in data usage.

- Security and access control: These are used to secure data and protect it from unauthorized access, and to control who has access to different data sets and storage resources.

- Safety: What measures are in place to ensure the safety of workers and the integrity of the stored products?

- Maintenance: What maintenance is required to keep the system running smoothly?

- Cost: What is the total cost of ownership for the system, including initial purchase price, ongoing maintenance, and utilities?

- System integration

- Implement the smart storage system:

- After you have designed the smart storage system, it’s time to put your plan into action. This may involve

- installing new equipment,

- training employees on how to use the new system,

- transitioning to the new system.

- After you have designed the smart storage system, it’s time to put your plan into action. This may involve

- Monitor and evaluate the system:

- Finally, it’s important to monitor the performance of the smart storage system and make any necessary adjustments to ensure that it is meeting your goals. This may involve collecting data on the efficiency of the system, tracking inventory levels, and measuring the satisfaction of employees and customers.

Standars for intelligent storage system

ome standards that relate to AS/RS include:

- ANSI/MH10.8: Automated Storage and Retrieval Systems (AS/RS)

- FISMA: Federal Information Security Management Act

- OSHA: Occupational Safety and Health Administration (standards related to worker safety)

- ISO 9001: Quality management systems

- ISO 14001: Environmental management systems

ANSI/MH10.8 is a specific standard that provides guidelines for the design, testing, installation, and maintenance of AS/RS. It covers a wide range of topics, including system performance, safety, and reliability. Other standards, such as FISMA and OSHA, address issues related to data security and worker safety in the context of AS/RS. ISO 9001 and ISO 14001 provide guidelines for quality and environmental management in the operation of AS/RS.

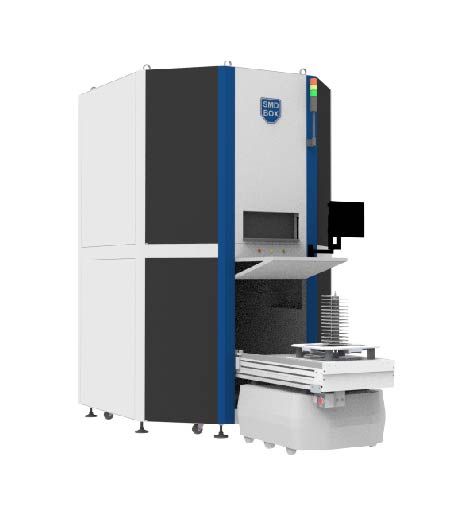

ionic contamination testing la manutention intelligente manipulation de la pâte à braser Materialeingangserfassung msd msd Neo-Licht Neo-Scan Neo-Zähler neo counter neo light neo light neo light neo scan neo scan neo scan plus neo station Neostation Neotel Technology Co. Prüfung auf ionische Verunreinigung smart material handling smd-box smd box smd box SMD BOX MIMO SMD BOX SPC Smt-Rollen smt reels solder paste handling spi spi station néo test de contamination ionique イオンコンタミネーションテスト ウェス スピ スマートマテリアルハンドリング ソルダーペースソリューション ネオスキャン ネオステーション ネオ・カウンター リール 半導体 汎発性分析 部材受入登録システム